In the era driven by technology and innovation, the breakthrough and application of high-end new materials have become the core driving force for the upgrading of various industries. Recently, Ibuychem has reached in-depth cooperation with Associate Professor Dr. Zhou Jian from the School of Materials Science and Engineering, Sun Yat-sen University, to jointly launch micro-nano fiber aerogel, a high-end new material. As the solid material with the lowest known density in the world, this material is comprehensively subverting the market pattern of traditional thermal insulation materials with its outstanding performance advantages, bringing revolutionary application changes to multiple fields.

Technological Innovation Unlocks New Heights of Material Performance

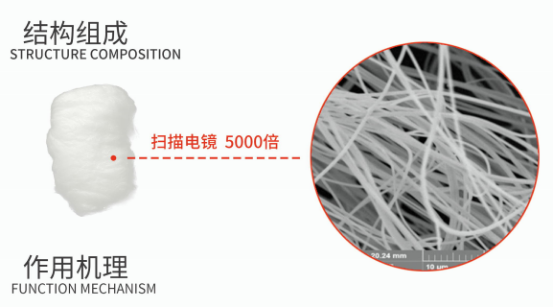

The micro-nano fiber aerogel developed through this cooperation has achieved a major breakthrough in structural composition and mechanism of action. Observed under a scanning electron microscope at 5000x magnification, a unique network skeleton structure is formed inside. Relying on the three core effects of “no convection”, “infinite baffles” and “infinite long path”, it builds a super thermal insulation barrier. The average pore size inside the material is only 20-50 nm, which is smaller than the mean free path of air (70 nm), effectively blocking air circulation; the network skeleton can not only shield thermal radiation, but also infinitely extend the heat conduction path, fundamentally improving the thermal insulation efficiency.

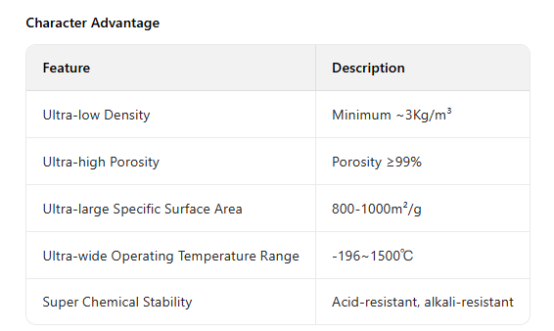

In terms of core performance parameters, the material shows overwhelming advantages: ultra-low density of only 5-50 kg/m³, far lower than 300-400 kg/m³ of traditional materials; ultra-high porosity of ≥99%, specific surface area of 800-1000 m²/g; operating temperature range covering -196℃ to 1500℃, adaptable to extreme environments; and super chemical stability, resistant to acids and alkalis. In terms of thermal conductivity, it is only 0.023 W/m·K at room temperature and still maintains an excellent level of 0.026 W/m·K at 400℃, far exceeding traditional glass fiber, asbestos and xonotlite composites. In addition, the material has outstanding characteristics such as strong cushioning performance, stable structure without powdering or slagging, safety, environmental protection and non-irritation. It is easy to construct, can be folded and cut arbitrarily, and completely solves many pain points of traditional thermal insulation materials.

Scenario Empowerment to Address Core Needs in Multiple Fields

New Energy Vehicle Field: Build a Strong Line of Defense for Battery Safety

With the continuous increase in the penetration rate of the new energy vehicle market, its annual sales in 2024 accounted for 40.9% of the total sales of new cars, and this proportion further increased to 53.2% from January to November 2025, officially surpassing fuel vehicles to become the market mainstream. Against the background of the rapid development of the industry and the continuous increase in vehicle ownership, the demand for fire protection of new energy vehicles has become increasingly urgent. The core safety links such as fire and heat insulation of battery compartments need to be strengthened, which also highlights the importance of the application of fireproof materials in new energy vehicles. The performance of fireproof materials is directly related to the vehicle safety level, and is also a key support for promoting the healthy and sustainable development of the industry.

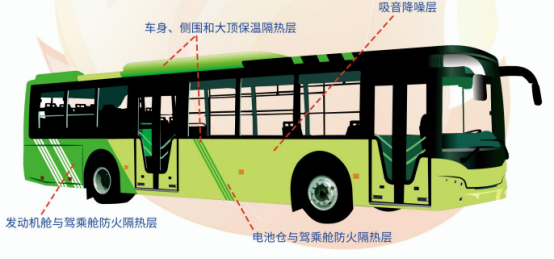

The aerogel thermal management insert developed through this cooperation can effectively block thermal runaway between single cells, maintain the stable working temperature of cells, and extend the service life of batteries; at the same time, it can absorb the volume expansion caused by battery charging and discharging, improve the space utilization rate of battery compartments, and has excellent insulation performance. In addition, the insulation layer of the battery compartment can slow down the heat exchange with the outside world, ensure the car use experience in extremely cold environments, build a “fire wall” for the battery compartment and the passenger compartment, and comprehensively protect the car use safety.

Construction and Building Materials Field: Create a New Benchmark for Energy Saving and Fire Prevention

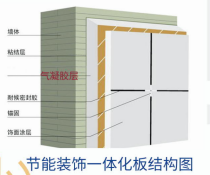

In response to the high requirements of low-carbon energy-saving buildings in China, after compounding the micro-nano fiber aerogel with wall material products, high thermal insulation composite products and components can be prepared, which greatly reduce the heat transfer coefficient and meet the needs of building energy conservation. In terms of fire performance, the material reaches the combustion performance grade A (A1) (GB8624 – 2012), which can effectively eliminate fire hazards and solve the industry problem of “wall insulation materials becoming accomplices in fires”. In 2024, there were about 190,000 self-built residential fires, resulting in 850 deaths, a year-on-year increase of 11.8% and 5.7% respectively compared with 2023 data. High-rise building fires surged from 23,600 in 2023 to 48,000, a year-on-year increase of 103.1%, with 260 deaths (year-on-year + 8.3%). The growth trend of the two types of building fires highlights the urgency of building fire safety. Among them, flammable insulation materials such as polyurethane foam and polystyrene are important reasons for the rapid spread of fire, the generation of a large amount of toxic smoke and the aggravation of casualties. Therefore, the application of high thermal insulation composite products with A-class non-combustibility, flame retardancy, smoke suppression and low thermal conductivity will provide an important guarantee for building safety.

At the same time, its porous structure has sound absorption and noise reduction functions, which can create a good living environment. Compared with traditional materials such as rock wool, the density of this aerogel material is only 5-20 kg/m³, far lower than 60-100 kg/m³ of rock wool. It is also mold-free, antibacterial and corrosion-resistant, with slender fibers without dust and no irritation to the skin. In construction, its characteristics of light weight, softness and good resilience are suitable for keel spacing, with less loss. A single person can carry 50-80 m² at a time, which greatly improves the construction, transportation and storage efficiency and reduces the comprehensive cost.

Industrial and Pipeline Field: Help Energy Saving, Carbon Reduction and Efficiency Improvement

In industrial scenarios such as petrochemical industry, metallurgical industry and cogeneration, the aerogel material shows super high temperature adaptability and energy saving advantages. When used for thermal insulation of 350℃ steam pipelines, compared with traditional materials, the insulation thickness can be reduced by 2/3, energy consumption can be saved by more than 40%, and carbon dioxide emissions can be reduced by 125 tons per kilometer of pipeline every year. When used for various high-temperature pipelines, it can reduce heat loss during transportation by 40%-70%. If high-temperature pipelines are fully adopted, national energy consumption can be reduced by 5%-7%, providing strong support for the achievement of the “dual carbon” goals.

In addition, the material is also widely used in transportation, purification and environmental protection, aerospace and other fields. In scenarios such as fire air duct engineering, fire and heat insulation of engine compartments and passenger compartments, its characteristics of lightness, high efficiency and safety are fully exerted, which not only saves space, but also achieves multiple protection functions.

Win-Win Cooperation Leading the New Direction of Industry Development

The cooperation between Ibuychem and Associate Professor Dr. Zhou Jian’s team from Sun Yat-sen University is a perfect integration of industrial resources and university scientific research strength. Relying on Sun Yat-sen University’s profound scientific research accumulation in the field of materials science, combined with Ibuychem’s advantages in industrial resource integration and market channel expansion, the micro-nano fiber aerogel material has achieved rapid commercialization from the laboratory.

The launch of this material not only fills the technical gap in the high-end thermal insulation material market, but also promotes the green transformation and safety upgrading of multiple industries. In the future, the two parties will continue to deepen cooperation, focus on technological innovation and product iteration in more application scenarios, let the high-end new material of micro-nano fiber aerogel exert greater value, and write a vivid footnote for technology empowering industry and innovation driving development. For more product details or technical support, please contact Ibuychem official assistant for professional services. You could also check the details of this product at https://www.ylcool.com/sjk/224520